Prodigy : Production Monitoring System

Background

Production lines often rely on fragmented tools, manual logs, spreadsheets, and isolated systems, that make it hard to see what’s happening on the shop floor in real time. This creates gaps in traceability, delays issue detection, and limits data-driven decision-making for supervisors and managers.

Prodigy was built as a full-scale Production Monitoring System to improve traceability, productivity visibility, and operational control by connecting real-time data capture on the line with web dashboards and API-driven integrations.

The Problems

- Limited real-time visibility into productivity (cycle time, output, downtime, headcount)

- Traceability gaps: difficult to track operators, products, and process history end-to-end

- Manual recording increases delays and errors, slowing down response on the shop floor

- Disconnected systems prevent consistent reporting and actionable insights

- Model change events disrupt flow and require fast, controlled updates on the line

Our Approach

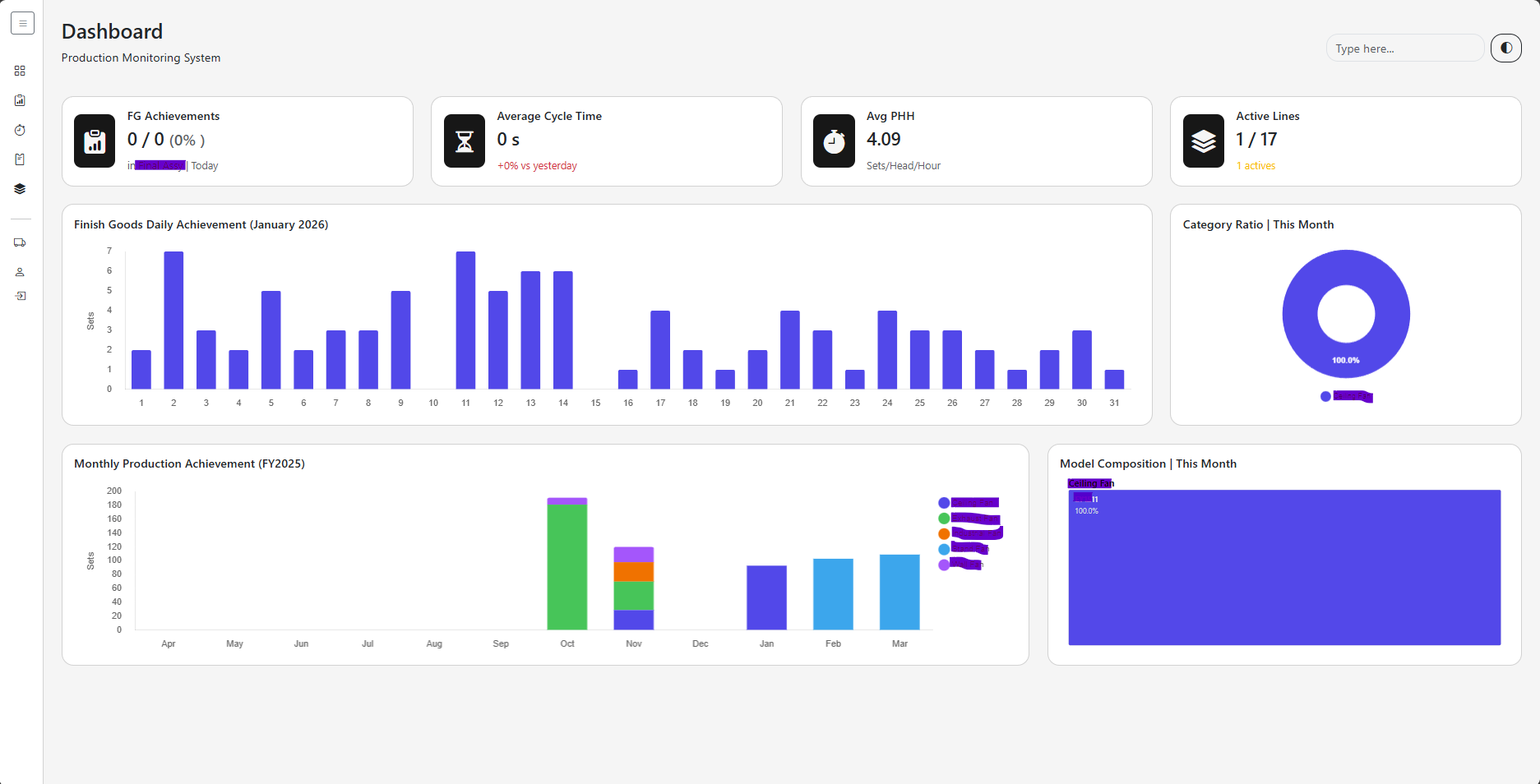

I designed Prodigy as an integrated ecosystem: desktop applications for real-time floor data capture, a web dashboard for management visibility, and robust APIs to unify communication between components. The system focuses on fast operator workflows, reliable data capture, and clear dashboards that translate shop floor events into actionable KPIs.

Key Contributions

- Developed desktop applications for real-time data collection on the production floor

- Built web-based dashboards to deliver actionable productivity and performance insights

- Created robust API integrations to ensure smooth communication across systems and platforms

Architecture

Shop Floor (Operators / Stations)

│

▼

Desktop Data Capture Apps

(barcode scans, cycle time, downtime, model change)

│

▼

API Integration Layer

(validation, business rules, logging)

│

▼

Central Database

(production plans, transactions, traceability records)

│

▼

Web Dashboards

(real-time KPIs, productivity trends, supervisor views)

│

▼

Production Display Monitoring

(live indicators for floor performance tracking)The system separates data capture, API logic, storage, and presentation so each part can evolve independently. This design keeps the shop-floor workflow fast while maintaining reliable data consistency for reporting and traceability.

Project Showcase

Swipe to preview production dashboards, plan tracking, barcode workflows, and traceability views.

Methodology & Key Features

- Production Plan Management – Schedule and track daily production targets

- Productivity Data Capture – Monitor cycle time, headcount, line capacity, and downtime

- Model Change Functionality – Quickly update product models with minimal disruption

- Barcode Scanning System – Operator identification, product tracking, and activity logging

- Traceability System – Track components and processes for product quality and compliance

- Interactive Dashboards – Real-time productivity insights for supervisors and managers

- Production Display Monitoring – Visual indicators on the shop floor for live performance tracking

Results

Prodigy improved visibility and control on the production line by centralizing plan tracking, real-time data capture, and traceability records into one system. Supervisors gained faster insight into performance issues, while management could make data-driven decisions using consistent KPIs and real-time dashboards.

Impact

- Improved traceability by linking operators, products, and process history end-to-end

- Reduced manual recording and improved accuracy of shop-floor events and KPIs

- Enabled real-time monitoring and faster response to downtime and performance drops

- Delivered actionable dashboards for supervisors and managers to drive productivity improvements

- Created a scalable foundation for future integrations across production lines and systems